Discover The Luxurious World Of Soft Touch: Benefits & Uses

Ever wondered how a simple touch can elevate the perceived value of a product? Soft touch finishes, with their unique ability to engage the sense of touch, are revolutionizing the world of packaging and print, creating an unparalleled sensory experience.

The allure of a soft touch finish is undeniable. It's a tactile experience that goes beyond the visual, creating a connection between the product and the consumer that's often missed in traditional design. The coating itself, once applied, dries to a texture that's remarkably soft, almost velvety to the touch. This isn't just about aesthetics; it's about creating a feeling.

Soft touch coating, often likened to rubber, presents a cool and inviting sensation when handled. Its a finish that not only softens the visual appearance of the product, giving colors a deeper, more refined look, but also transforms the physical experience, enhancing the overall perceived quality. This makes soft touch finishes highly appealing across a variety of applications. Consider the difference: a standard brochure versus one that feels luxurious, and your fingers glide over the surface.

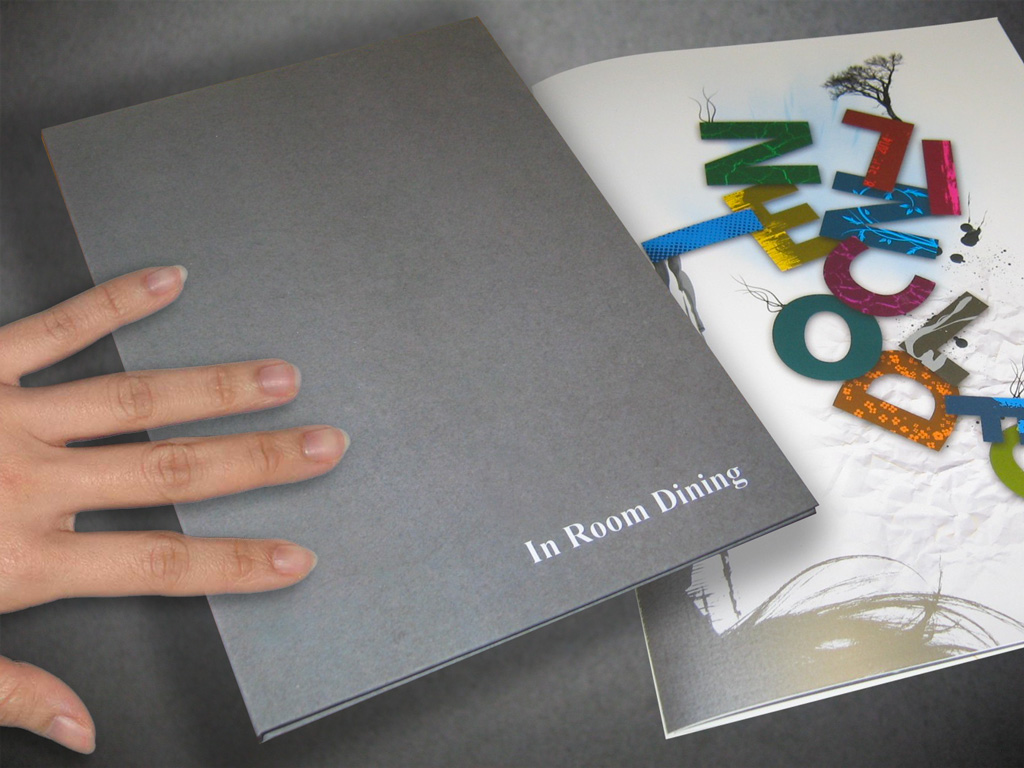

This tactile element sets soft touch finishes apart from visual-centric design elements. It's about making a lasting impression. Companies have embraced this finishing method extensively, particularly for luxury packaging. High-end product fact sheets, sophisticated brochures, elegant book covers, and premium paper boxes all benefit from the application of a soft touch coating. This enhances the unboxing experience, which is why it is so popular in modern product design and marketing.

Soft touch lamination is a premium option that caters to two primary senses: touch and sight. It delivers a visual experience that often mimics matte lamination but goes a step further by adding a soft, silky feel. This adds a luxury element. It is often called the "Rolls Royce" of print finishing, offering high-end quality without the premium price tag.

The versatility of soft touch finishes is noteworthy. They improve the design of any product, whether packaging or marketing materials. The durability and pleasant feel contribute to a more engaging and memorable unboxing experience. From the moment a consumer interacts with the packaging to the moment they've opened their new product, the touch is crucial.

While the terms "soft touch coating" and "soft touch lamination" are often used interchangeably, the primary difference lies in the application process. One is a coating, and the other is a lamination. They both alter the feel of the printed material. A professional will guide you on which method is best for your unique printing project, taking into account factors such as budget and the intended use of the final product.

Beyond print finishing, the "soft touch" concept appears in other fields. Consider the Finishing Touch Flawless product line, known for its personal care items. These products often include soft touch elements to enhance the user experience, particularly the Finishing Touch Flawless Facial Hair Remover. These devices aim to provide a smooth, comfortable experience, focusing on gentle hair removal without irritation or the disadvantages of traditional methods.

In the realm of automotive care, "One Touch Finish, LLC," based in Bensalem, PA, provides professional mobile car detailing. Their comprehensive services, from exterior detailing to interior rejuvenation, including leather seat conditioning and paint correction, represent the idea of providing a "finishing touch" for vehicles, restoring their appearance to a like-new condition.

The language also has its own meaning. In the context of American Sign Language (ASL), the phrase "finish + touch" means "have been to" or "have gone there before." This illustrates the multifaceted nature of the phrase "finish touch", crossing over different fields.

The "finishing touch" is a versatile term used across many industries. It refers to the final steps taken to perfect a product. In the world of printing, this might mean the application of a soft touch coating to a brochure or a book cover. In product development, it means the last details to give a polished and complete feel.

The use of soft touch finishes, in marketing materials like business cards, demonstrates the impact of this technique. Soft touch provides a soft, supple feel that elevates a simple business card into a premium marketing tool. It can soften colors and reduce contrast, lending the design a muted, elegant appearance.

The Repelflex ST soft touch coating, designed for plastic substrates, provides a durable, silky surface for tables and furniture. The coating, used both indoors and outdoors, demonstrates the appeal of soft touch and its application for elegance and refining the texture of things that we use.

While applying a soft touch finish has many benefits, it is vital to be aware of its limitations. In terms of print design, light colors and gradients do not show well. In these cases, darker colors are often preferred. The effect of this finish alters the way colors are perceived, and the designer must account for this.

| Feature | Details |

|---|---|

| Definition | A tactile finishing method applied to printed materials, offering a soft, velvety texture. |

| Tactile Experience | Simulates a rubbery texture, providing a nice and cool sensation when touched. |

| Visual Impact | Softens the appearance of printed materials, giving colors a deeper, more refined look. |

| Appeal | Highly appealing in luxury packaging and marketing collateral due to enhanced feel and appearance. |

| Common Applications | Used in product fact sheets, brochures, book covers, paper boxes, corrugated boxes, and paper bags. |

| Lamination Type | A luxurious lamination type offering a soft, silky feel, similar to matte lamination. |

| Benefits | Enhances product design, enhances the unboxing experience, and increases the perceived value of the product. |

| Key Features | Versatility, durability, and a pleasant feel. |

| Application | The difference between soft touch coating and lamination lies in their application process. |

| Usage | For enhancing the product design with a more appealing look and feel. |

| Marketing Collateral | Widely used for brochures, book covers, and luxury packaging. |

| Unboxing Experience | Enhances the unboxing experience for consumers. |

| Finishing Methods | Soft touch coating and soft touch lamination are common finishing methods. |

| Perception | Transforms the physical experience by creating a premium feel. |

| Material | Typically a premium plastic film. |

| Color Impact | Softens colors and reduces contrast, leading to a lighter and muted appearance. |

| Durability | Provides a highly durable surface, suitable for a wide range of uses. |

For more details, you can check this website printing.com